Surface Facility Software

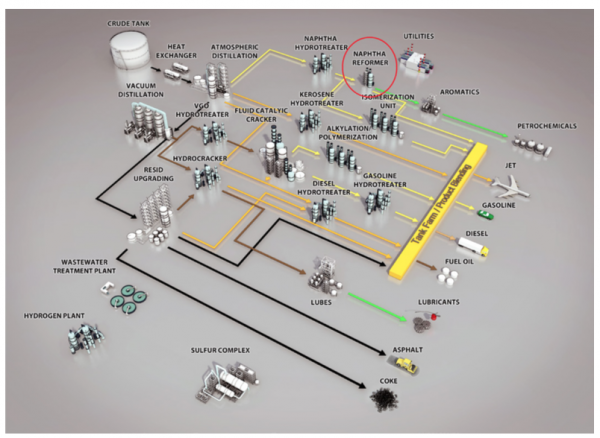

Oil & Gas Surface Facility include layout of surface flow lines to handle oilfield production at the surface, the treatment equipment, and the processes to transfer liquid. The surface gathering systems, separator, fluid treatment, piping, pigging, transportation and fluid volume measurements are all part of surface facility (down-stream) design.

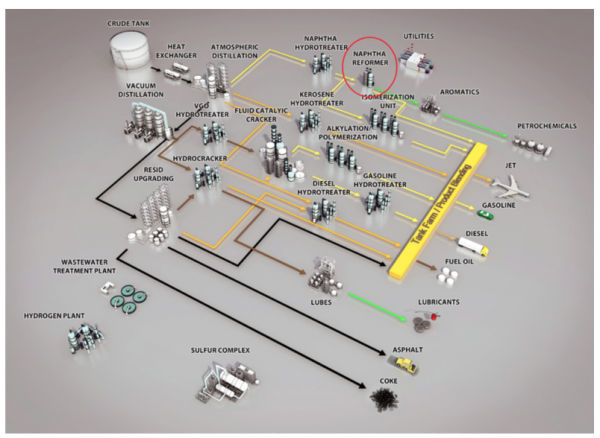

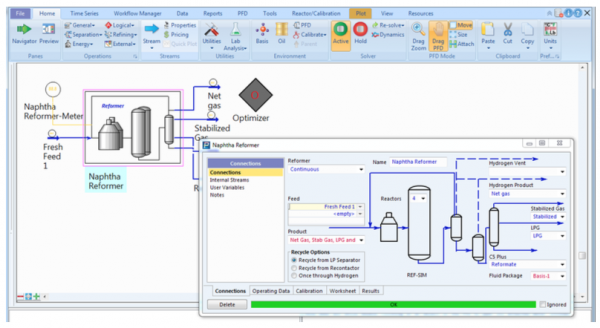

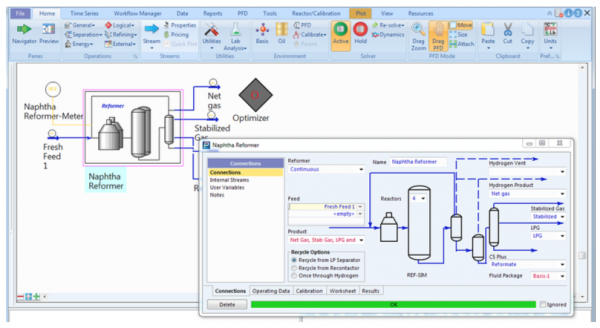

Are you trying to maximise hydrogen production? Optimise gasoline blending against stringent sulphur and benzene specifications? Are you concerned with minimising yield loss across your reformer? Do you need to maximise aromatics production for downstream petrochemical processes? Are you concerned w ...

Read More ...

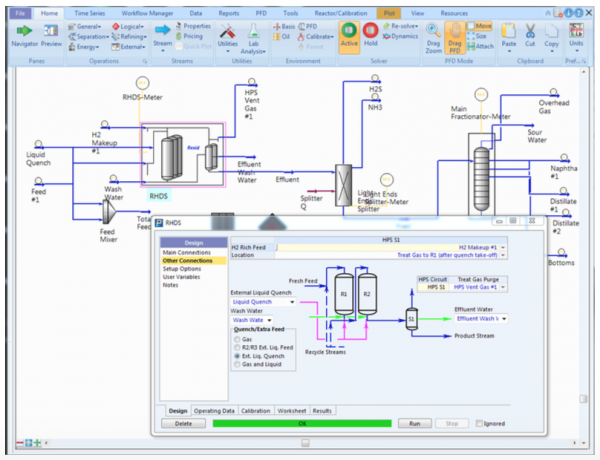

Are you trying to determine how a particular feed will affect catalyst run length? Are you hydrogen constrained and need to understand the real hydrogen demands within your refinery? Are you concerned with the impacts that changes in your hydrotreater will have on downstream units? Are you trying to ...

Read More ...

Do you target maximum aromatic saturation or final product sulphur when determining operating temperatures in your hydrotreater? Are you trying to determine how a particular feed will affect catalyst run length? Are you hydrogen constrained and need to understand the real hydrogen demands within you ...

Read More ...

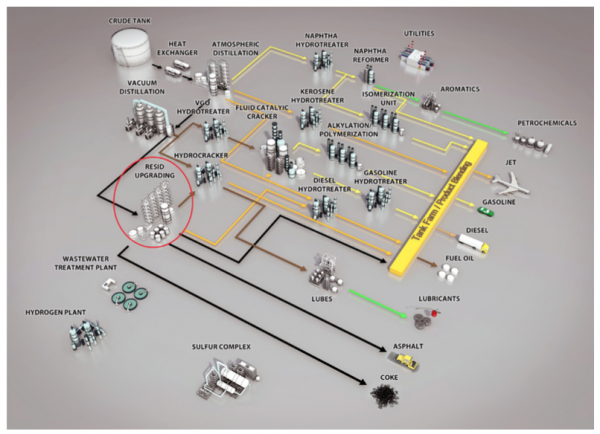

Do you struggle to determine the optimal set of operating conditions to achieve the highest conversion while still making a stable fuel oil product? How do you manage the performance of your furnace? Do you have concerns with regards to furnace fouling? Are you trying to increase your furnace run le ...

Read More ...

SuperTarget™ Popular

Reduce energy costs by 10-30% and minimise the capital spend when designing or revamping heat exchanger systems, by using SuperTarget to perform Pinch-based analytics.

Despite the fact that Pinch Technology is well documented and has supposedly been applied since the early 1980s, energy benchmarkin ...

Read More ...

Fouling related issues cost a typical 100KBD refinery $1-2M per year compared to those with a HX Monitor exchanger management system. Fouled exchangers cost money due to increased energy use and lost production when furnaces become a constraint, and exchanger cleaning incurs direct costs of chemical ...

Read More ...

Speed up gas turbine selection, and make design iterations faster when optimising a system with a gas turbine and a production process, to allow faster decision making and a deeper level of optimisation without the conservatism and assumptions normally used.

When sizing a gas turbine and associated ...

Read More ...

Are you trying to maximise hydrogen production? Optimise gasoline blending against stringent sulphur and benzene specifications? Are you concerned with minimising yield loss across your reformer? Do you need to maximise aromatics production for downstream petrochemical processes? Are you concerned w ...

Read More ...

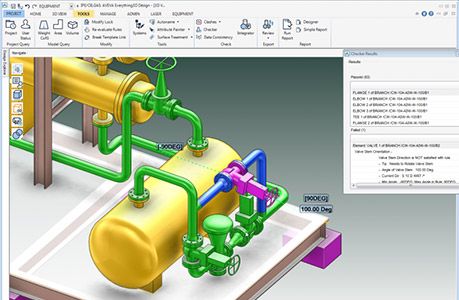

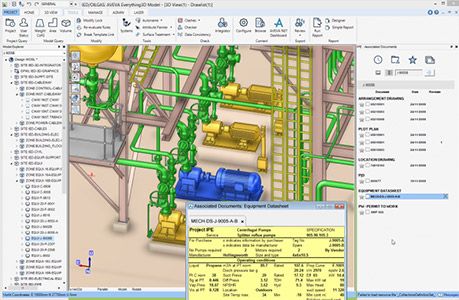

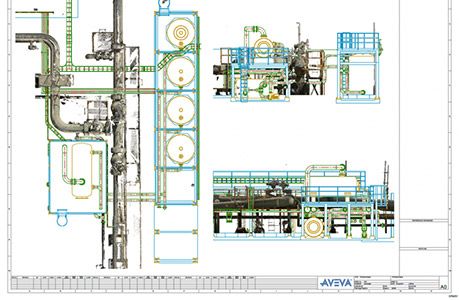

AVEVA Everything3D, Reducing Cost, Timescale and Project Risk

AVEVA Everything3D exploits the latest technology innovations in mobile computing, Cloud computing and laser scanning to enable Lean methods in plant project execution. It takes the plant industry to a new level of capability, reducing c ...

Read More ...

Design and Optimize Chemical Processes with Aspen Plus®.

Aspen Plus is the market-leading chemical process optimization software used by the bulk, fine, specialty, & biochemical industries, as well as the polymers industry for the design, operation, and optimization of safe, profitable manufact ...

Read More ...