Surface Facility Software

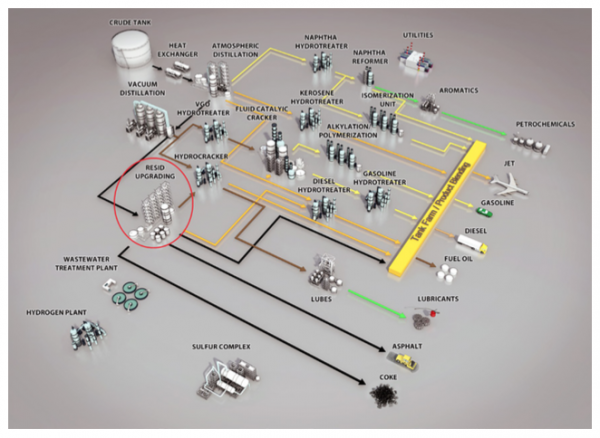

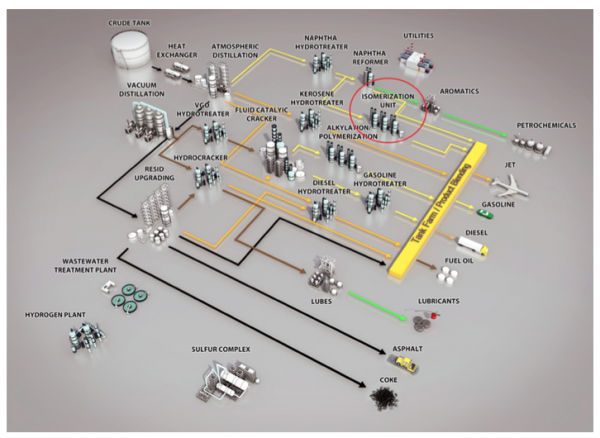

Oil & Gas Surface Facility include layout of surface flow lines to handle oilfield production at the surface, the treatment equipment, and the processes to transfer liquid. The surface gathering systems, separator, fluid treatment, piping, pigging, transportation and fluid volume measurements are all part of surface facility (down-stream) design.

Maximise facility performance and margin capture

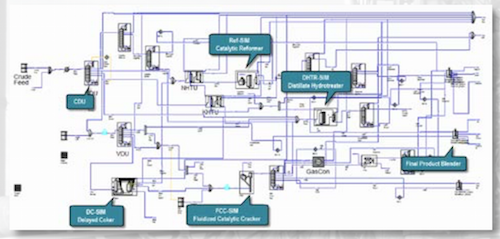

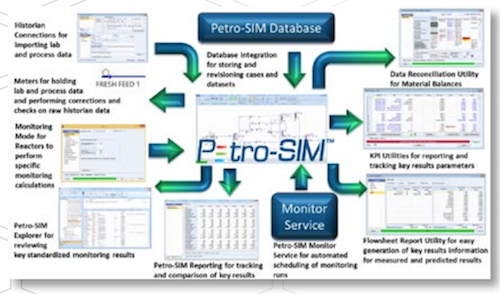

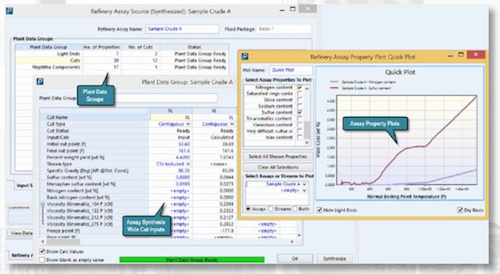

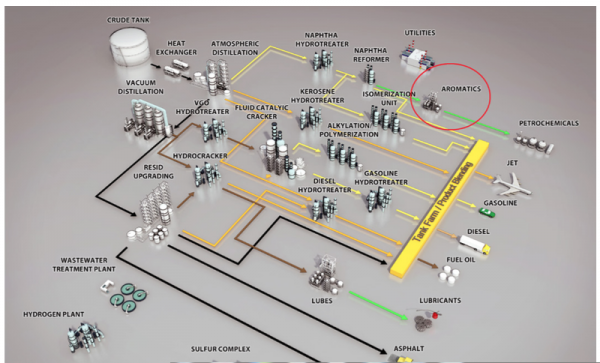

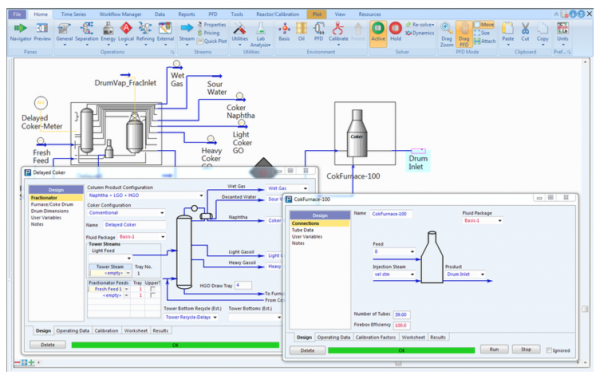

Petro-SIM is the only proven process simulator that scales from the reactor unit to the entire facility while combining the rich DNA of process simulation with integration to best-in-class KBC and third party software to create leading edge technolog ...

Read More ...

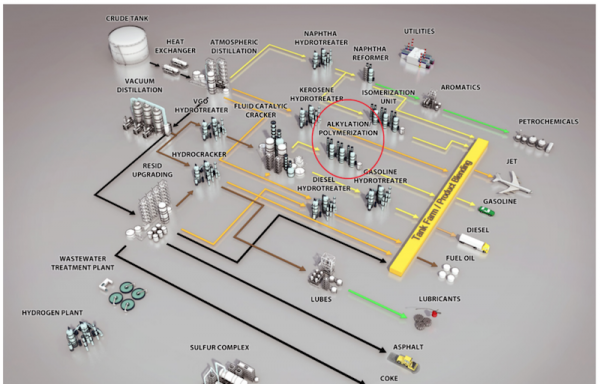

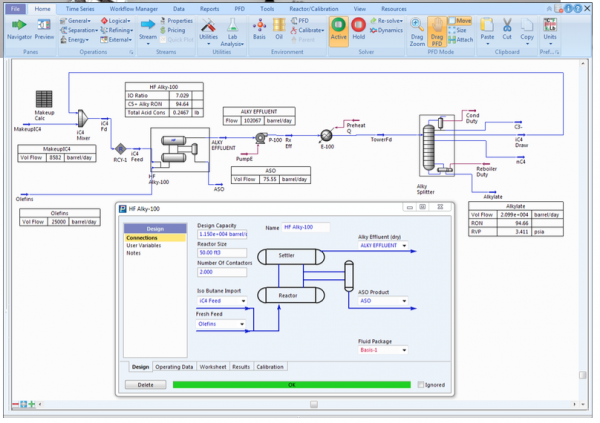

Alkylation is a key process that creates high-value products from intermediate refining streams. Use ALK-SIM, proven over decades of use within refineries worldwide, to evaluate alkylation of various C4 and C5 olefin isomer feeds under different scenarios of iC4/olefin ratio, reactor temperature and ...

Read More ...

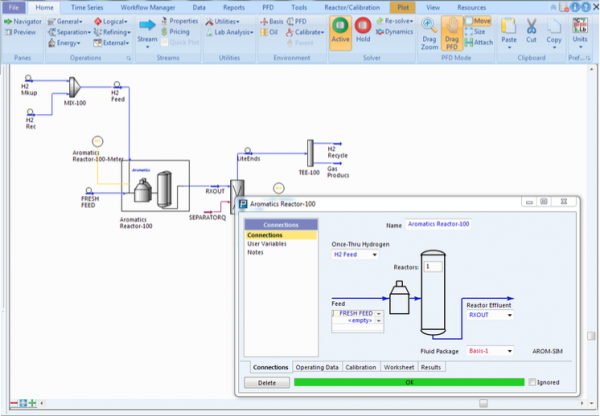

At the heart of aromatics plants are reactors that are governed by complex kinetics. Modelling these units requires sophisticated software, that is still easy to use. KBC’s AROM-SIM combines the key aromatics reaction systems of xylene isomerisation and transalkylation in a single software modelling ...

Read More ...

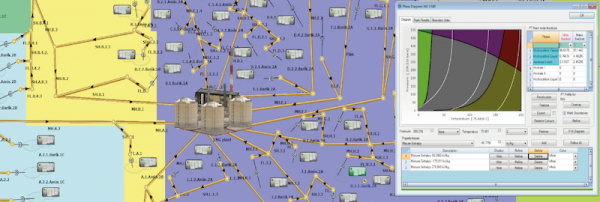

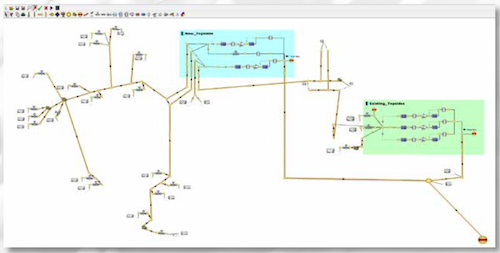

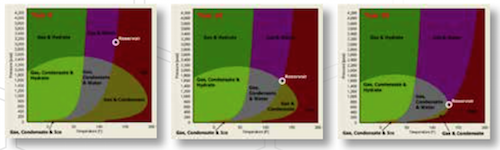

Maximus™ Thermal Hydraulic Integrated Production Modelling Software

Maximus can be used like any other steady state pipeline network simulator and has been designed to be easy for users familiar with such tools to pick up and use it for nodal analysis, network sensitivity studies and single design ...

Read More ...

Delayed coking is a key process used in many refineries to convert residual streams to more commercially viable products. Delayed cokers present numerous unique operational and safety challenges not faced in other process units. How do feedstock quality changes affect liquid product yields? Coke pro ...

Read More ...

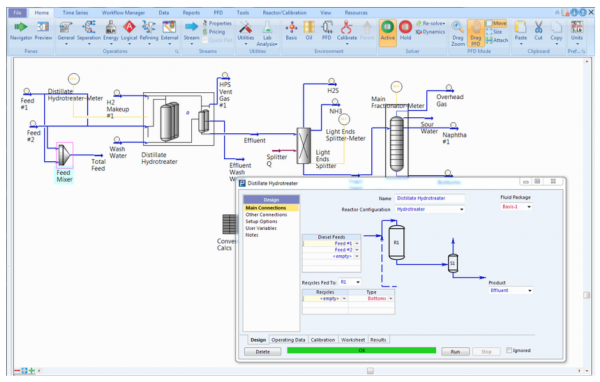

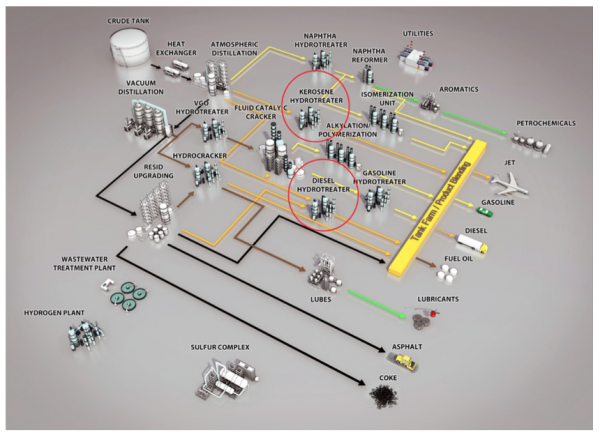

Hydrotreating operations are key to adhering to finished product regulations and operating downstream units effectively. How will various feeds perform in your hydrotreater with respect to hydrogen consumption, effect on ultimate catalyst run length and product qualities? D HTR-SIM can help determin ...

Read More ...

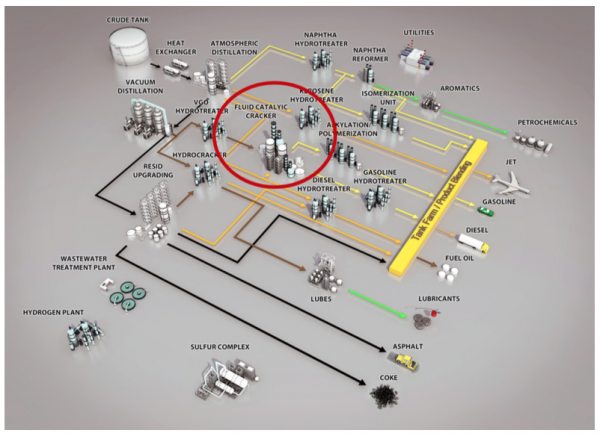

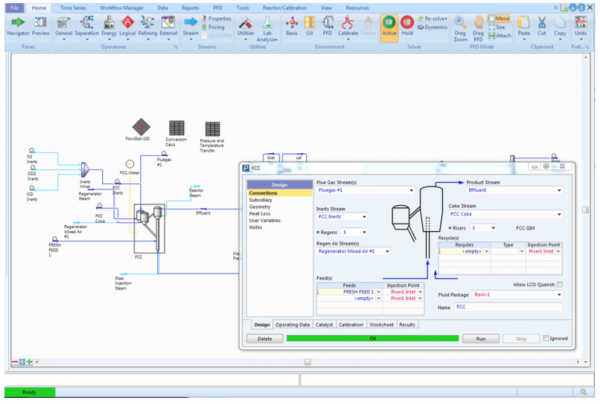

FCC unit operation is a key economic driver in many refineries. Do you need to evaluate feed alternatives for your unit? Are you air blower or regenerator constrained? Do you need to decide whether to push feed rate or conversion? FCC-SIM can help determine the answers to these important questions. ...

Read More ...

Are you wondering what the optimum severity to run your hydrocracker is given changes in final product demands? Are you trying to balance severity against desired run lengths? Are you hydrogen constrained and need to understand the real hydrogen demands within your refinery? Are you trying to balanc ...

Read More ...

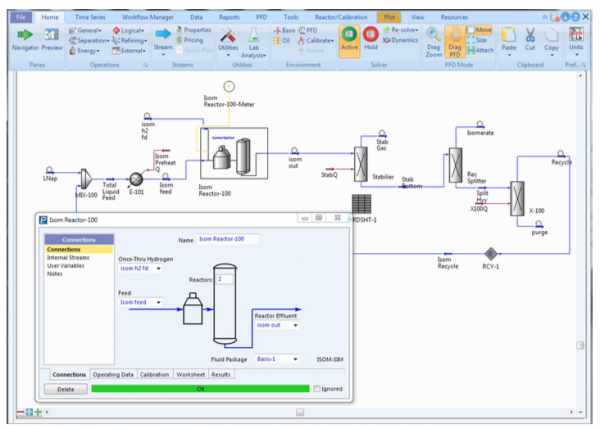

Are you trying to optimise gasoline blending against stringent sulphur and benzene specifications? How do you determine which temperatures to operate your isomerisation reactors at to maximise isomerisation and minimise cracking or other undesired reactions?

KBC’s kinetic isomerisation model ISOM-S ...

Read More ...

Are you trying to determine how a particular feed will affect catalyst run length? Are you hydrogen constrained and need to understand the real hydrogen demands within your refinery? Are you trying to understand the impact that silica poisoning will have on catalyst deactivation? Are you concerned w ...

Read More ...